Every year, the insurance industry sees losses from fires that are started by poorly maintained electrical panels, wiring, and underrated circuit breakers or fuses. Losses can also arise from machinery and equipment that are overused, improperly used, or poorly maintained.

Preventative maintenance (PM) of property and equipment is crucial in keeping them in working condition. A preventative maintenance program can save you time and money as it minimizes equipment breakdowns and expensive repairs that can affect your operations.

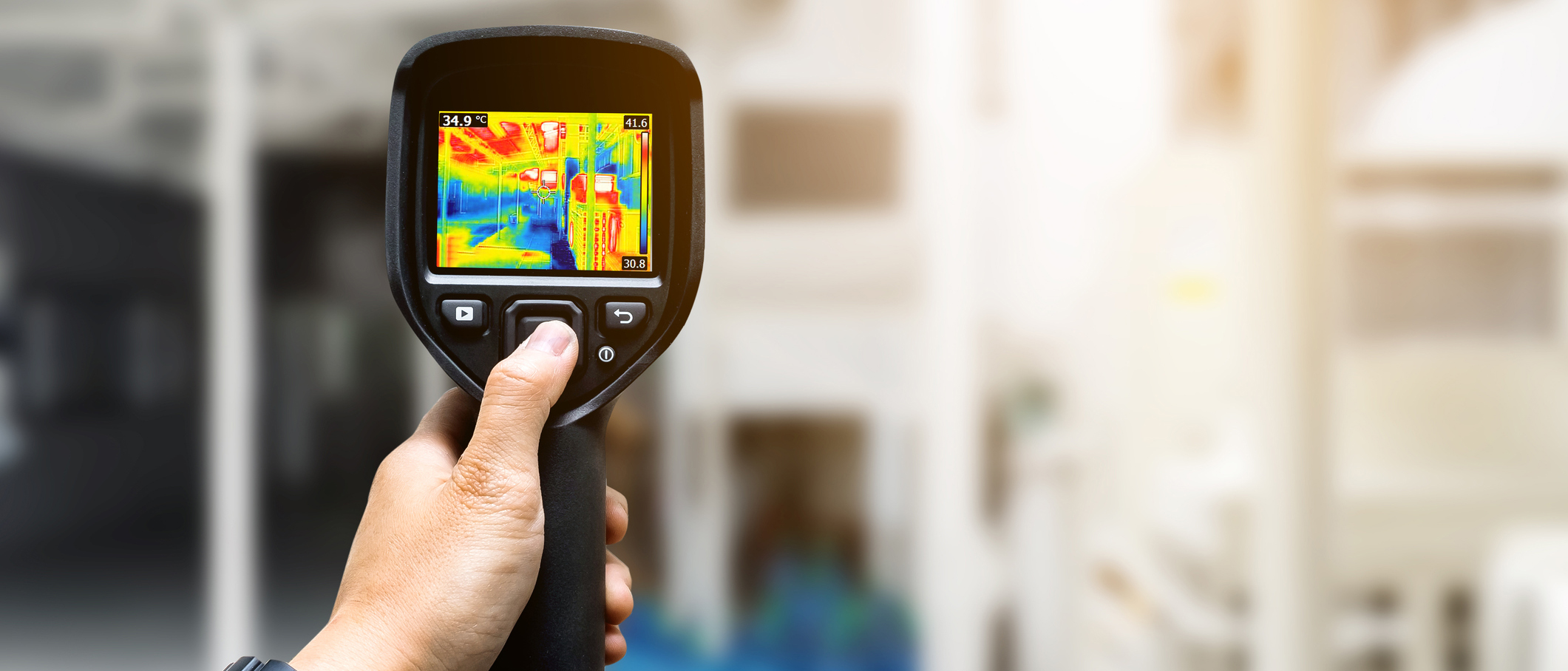

When thermal imaging is part of a preventative maintenance program, it brings value, minimizes damages, and reduces potential issues. Conducting thermal imaging on electrical or mechanical equipment can improve operational efficiencies and reduce potential problems before they arise.

You can prevent losses by including thermal imaging in your PM program. This reduces the likelihood of business downtime, the loss of production, and the loss of an entire facility

What is thermography?

The process of conducting thermal imaging is also known as thermography. Thermography is the study of heat distribution and looks at visual pictures of thermal data. A thermal image is generated by a thermal camera. Thermal imaging cameras collect infrared radiation from objects in a scene, which creates an electronic image. It can also be defined as the technique of using the heat given off by an object to produce an image which can then be analyzed further with specialty software.

How can thermal imaging help?

Thermal imaging can help you minimize damage as it displays an immediate assessment of hot spots and moisture. The potential benefits of having scans performed on a regular basis, as a part of your PM program, is to reveal deficiencies in insulation and electrical systems, roof leaks, radiant floor heating leaks, and other issues associated with the structure of the building. You can definitively capture water damage through thermal imaging as it can detect surface temperature differences (hot versus cold) between materials. Since water retains heat, the change in temperature usually indicates dry versus wet material.

When thermal imaging is conducted on a high voltage electrical system, its components, such as circuit breaker panels, wiring, connection points, and transformers, are reviewed for anomalies. Electric motors, pumps, and production machinery can be imaged as well. Thermal imaging of any apparatus should be done while the maintenance staff is on-site so that problems can be identified and resolved swiftly.

Thermography reports depict a snapshot or a series of snapshots of the particular area you’ve focused on. In the report, each section displays a digital photo of an object, followed by a thermal image of the object for comparison. The thermal image indicates the thermal temperature range, the maximum temperature area, as well as reference points. Each area of concern is described, followed by an observation or recommendation.

What can thermal imaging be used on?

- Buildings:

Heat loss and infiltration can come from deficiencies in insulation. A thermal image can illustrate issues with insulation or potential damage, such as plumbing leaks and condensation. Under the right conditions, structure components can be imaged. The intrinsic qualities of the building structure can reveal missing or altered structural components. - Roofs:

Scans can see failures, leaks, and moisture retention on roofs. They show water intrusion and accumulated moisture below the surface. Water, which has high thermal capacity, typically gives off heat at a much slower release rate than the surrounding roof materials. As a result, moisture that accumulates can be detected. Assessments of roof surfaces are best done during evening hours, after the daytime thermal energy has elapsed, transferred, or released. Most roof failures occur within the first seven years. - Electrical:

Deficient connections between components can result in overloads. A thermal image captures this as an apparent temperature elevation and compares it to similar load conditions of similar connection types or the ambient temperature. Thermal imaging can also determine transformer issues, which involve oil levels. - Mechanical:

When operating under normal load conditions, thermal imaging can detect excessive friction, non-uniform heat flow, temperature distributions, motor and bearing wear, pipe insulation, and tank levels in equipment and machinery. Thermal imaging should be conducted whether your property or operation is small or complex. Thermal imaging may be beneficial to owners of larger buildings or older structures containing older electrical components, exposed wiring, high valued or critical production machinery, and boilers.

Ensure that you’re protected

While it’s important to incorporate risk management practices, like thermal imaging, into your business continuity plan, things can still go wrong despite your best efforts. That’s when insurance can be helpful. To learn more about how a tailored policy can help protect you, your employees, and your bottom line, visit our Commercial Property Insurance Page.

This blog is provided for information only and is not a substitute for professional advice. We make no representations or warranties regarding the accuracy or completeness of the information and will not be responsible for any loss arising out of reliance on the information.